| Sign In | Join Free | My chinacsw.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinacsw.com |

|

Brand Name : AVIC-Flight

Model Number : M2-M16

Certification : ISO9001:2015,ROHS

Place of Origin : China

MOQ : 100pcs

Price : 0.5-1CNY/pcs

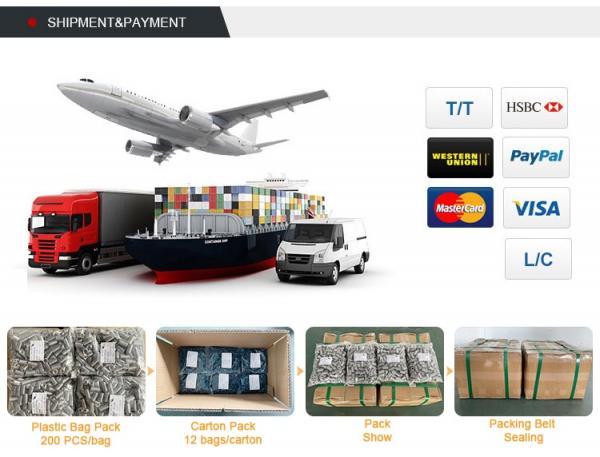

Payment Terms : D/P,T/T

Supply Ability : 20000pcs/day

Delivery Time : 5 work days

Packaging Details : 100pcs/bag

Name : self tapping thread insert

Coating : Zinc plated, Blue passivated,Yellow chromated,Transparent passivated

Material : 308SS

length : 6mm

Precision : 6H

Feature : High tensile strength

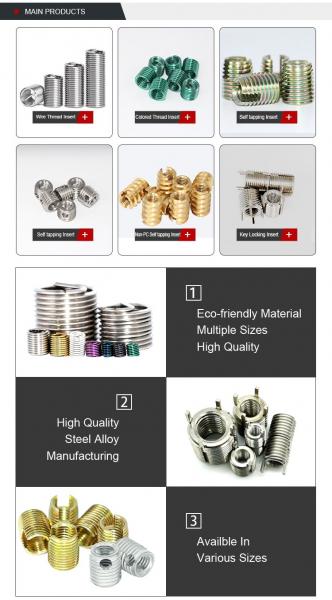

High precision Fasteners 308 Self Tapping Thread Insert

Introduction

Self-tapping threaded sleeves are also called self-tapping threaded sleeves. They are a new type of fastener that enhances the thread strength. Self-tapping threaded sleeves have tooth patterns on the inside and outside. They are embedded in softer materials such as plastic, aluminum alloy cast iron, and copper to form a relatively High-strength internal threaded holes, self-tapping screw sleeves (self-tapping braces) can also repair damaged internal threads.

302 type is the most widely used in all self tapping screw sleeve products. Its two slots not only play the role of cutting, but also have a little inward locking force.

Model 303 is a thin-walled version of 302 series, which is mainly used in some plastic or light alloy that cannot have thick wall.

Parameter

| Options | |||||||||

| Model | 302 | 303 | 307 | 308 | |||||

| Material | Stainless steel | Carbon steel | |||||||

| Standard | KKV | ||||||||

| Model | Metric | M3 | M4 | M5 | M6 | M8 | M10 | M12 | M16 |

| British | 6-32 | 8-32 | 10-32 | 1/4-20 | 1/2-13 | 5/8-11 | |||

| Accuracy | Green | Red | Golden | Blue | Non | Customized | |||

For difficult to cut materials, it has larger wall thickness, shallower but sharper external thread. The screw sleeve uses three round holes as cutting edge. The difference between 307 and 308 is the length of the insert.

Installation method

Self-tapping screw sleeve installation method

1: When the number of installations is small, a simple installation method can be adopted. Specifically, the method of corresponding specification bolt + nut is adopted, and the self-tapping screw sleeve is fixed on the bolt of the corresponding model, and the nut of the same model is used Fix it to make the three into a whole, then use a wrench to screw the screw sleeve into the bottom hole, and then pull out the bolt.

2: When the number of installations is large, special self-tapping screw sleeve installation tools can be used, first install the self-tapping screw sleeve on the special tool, and screw the installed screw sleeve into the pre-made hole about a circle , After ensuring that the tool is perpendicular to the end face of the prefabricated hole, screw in the screw sleeve forcefully. When the end face of the self-tapping screw sleeve is about 0.2mm lower than the end face of the prefabricated hole, stop screwing in and screw out the special tool in the reverse direction. The end of the self-tapping screw sleeve installation tool is a hexagon head, which can be connected with a manual tapping wrench, or an electric or pneumatic tool.

Installation Precautions

1. For different processing materials, refer to the drilling size specifications for pre-drilling processing. When the hardness of the corresponding material is high, please slightly increase the bottom hole in the drilling range.

2. The slotted end of the screw sleeve is downward, and the self-tapping screw sleeve is completely installed into the front end of the tool, and it must be in vertical contact with the workpiece. When installing (1~2 pitch), please make sure to align the bottom hole and never tilt. When you find that it is tilted, please do not reverse the tool and readjust it before use. After entering 1/3~1/2, you cannot start again. In addition, please do not rotate the tool in the opposite direction, otherwise it will cause the product to malfunction.

3. The self-tapping screw set should be at least 1mm lower than the surface of the part after matching

|

|

Carbon Steel 1/2-13 308 Self Tapping Thread Insert High Precision Fasteners Images |